Which Scale Should I Use?

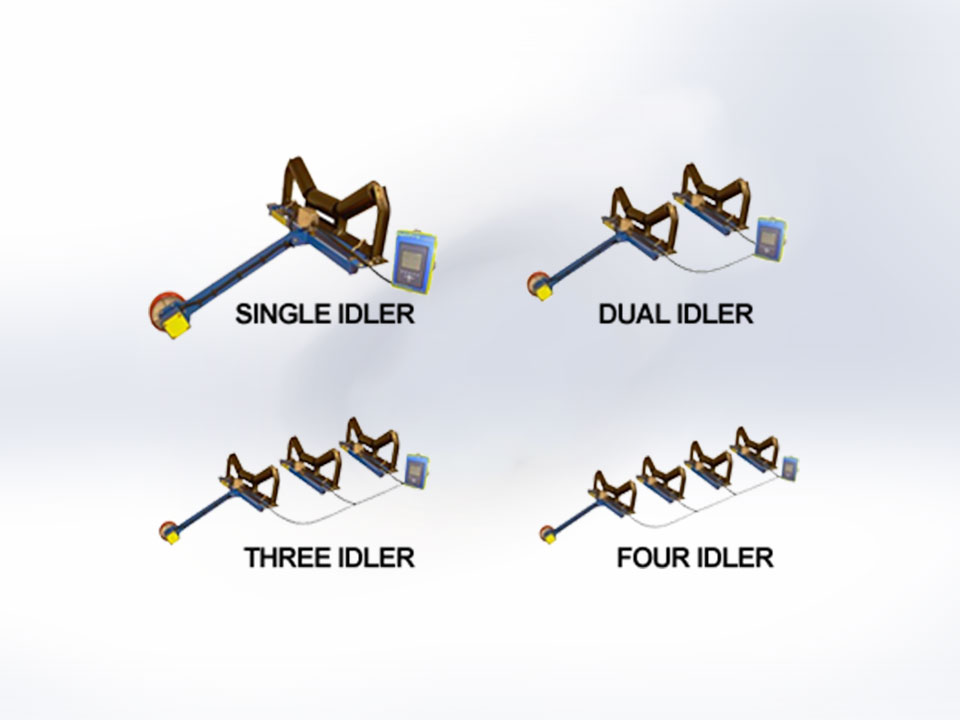

ConveyWeigh offers conveyor belt scales in the one, two, three and four idler models. The more weighing idlers you have in your belt scale increases accuracy. It is a matter of the electronics having more time to do it’s job and adding weigh idlers increases the time the integrator has to sample the weight signal. Determining which belt scale you need depends on how accurate you need it to be.

Our single idler model will typically deliver between 1 – 2 % accuracy depending on the quality of the belt, solidity of the belt structure, belt speed, scale loading, belt tension device and wind effect. We have seen single idler scales provide .25% accuracy and we have seen them struggle to provide 2% accuracy.

Much depends on the application. We highly suggest that you determine what type real world accuracy you require and then take the time to fill out the Quotation Request and let us review it. We can give you a good idea of how well any particular scale will function in your application. ConveyWeigh stands ready to help you determine which model of our scales will get you to the accuracy level you need. Just give us a call.

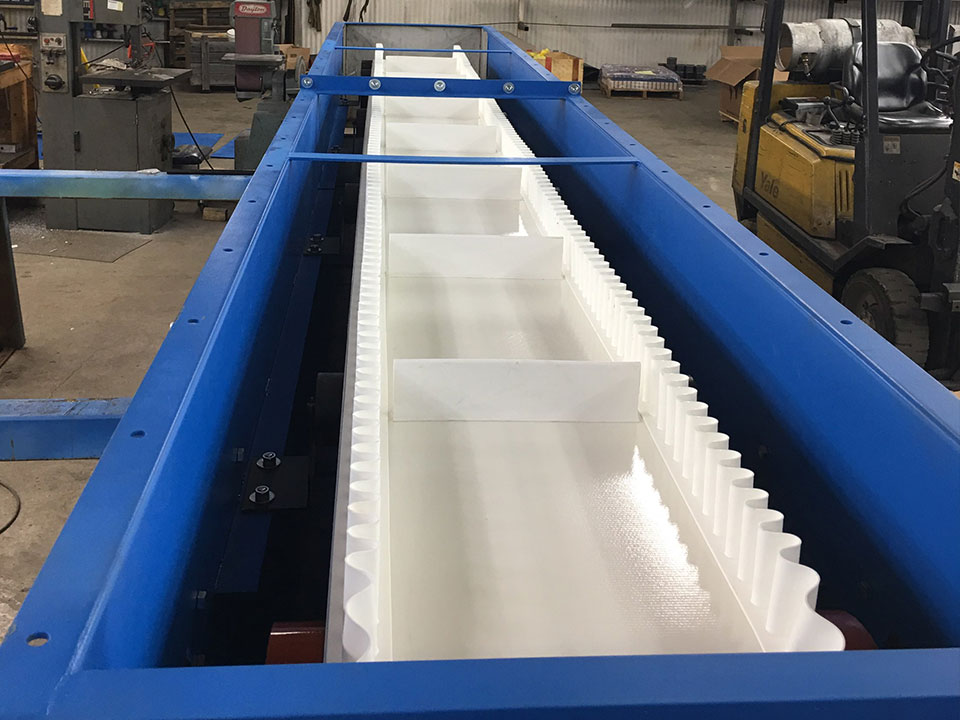

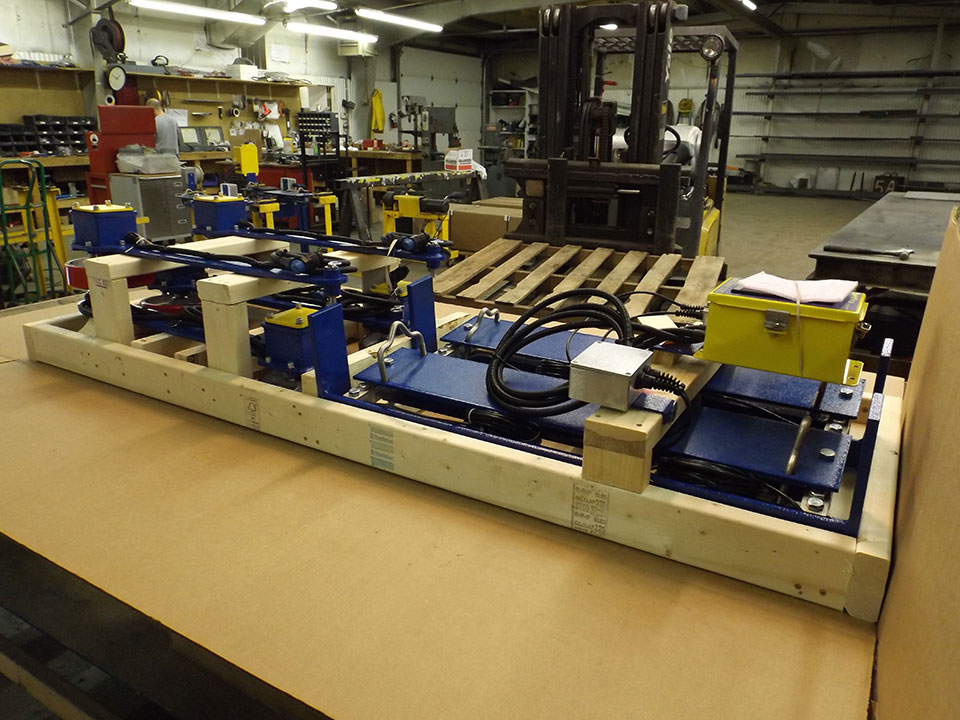

Weigh Feeders

Convey Weigh Belt Pro Weigh Feeders are each custom built per application. Our Weigh Feeders offer “State of the art” components and matching technology. Convey Weigh Weigh Feeders are variable speed relatively short conveyors constructed of stainless, zinc coated, or mild steel (painted) framing. Each Weigh Feeder utilizes a custom built full suspended scale frame. Weigh Feeders are designed for variable programmed bulk material/s flow rates and downline equipment control. Designed for light duty or heavy duty applications with remarkable accuracy at (+/-) 0.5% -.025% or better. PLC / man interface. Multiple inputs and custom programming available.

Weigh Feeders are usually installed under a feed bin for use in conjunction with any bulk material. Designed to control flow rates of the materials and any “in line” process via rate (weight/speed): such as blending and extracting specified amounts of material, at determined rates, additives in ratio programming, with EZ man machine interfacing, custom programming, with analog or digital communication to all PLCs. Custom PLCs available. Multiple Weigh Feeders in communication with each other ensure steady flow rates and production in synchronized ratio. weighfeederCommonly utilized for Plastics, Bulk Foods, Recycling, Concrete, Cement, Aggregates, Grains, Fertilizers, & all dry powders etc. Drawings to specifications for approval offered.

Conveyor Scales

ConveyWeigh, LLC offers Weigh Belt Conveyors, complete custom built Weigh Belt Conveyors, of any length, with any type idlers, or pan styled belt support systems. Often a single idler, two idler, three idler or four idler belt scale will be utilized depending on accuracy requirements. Our custom built Weigh Belt Conveyors provide outstanding accuracy. These weighers are incorporated into a custom conveyor design per application. Variable drive, load cells and complete conveyor wash down features available. Each conveyor will be equipped with a high resolution, 1000 pulse per revolution absolute speed encoder and will be wash down stainless steel construction.

Each conveyor is equipped with a Convey Weigh “Belt Pro” integrator with at least 4 load cell inputs, high resolution speed input, Ethernet rate output to PLC options, pulse type totalizer output options and all standard weigh belt scale and calibration software features. Wash down rated and NEMA 4X construction rated. FDA approved belting etc available. Analog or digital outputs to PLC. Custom controls, software, and multiple output PLCs available. Wifi, PC, Tablet & smart phone ready. Wireless or hard wired direct to PC from scale weight integrator. Multiple data outputs, RS 232, RS 485, Cat 5 – T- 10/100, USB-memory stick, 4-20-Ma 0-10v etc. Custom programming data software available. PLC Ready. PLCs available.

Commonly utilized for Plastics, Bulk Foods, Recycling, Concrete, Cement, Aggregates, Grains, Fertilizers, & all dry powders etc. Drawings to specifications for approval offered.

Modular Scales

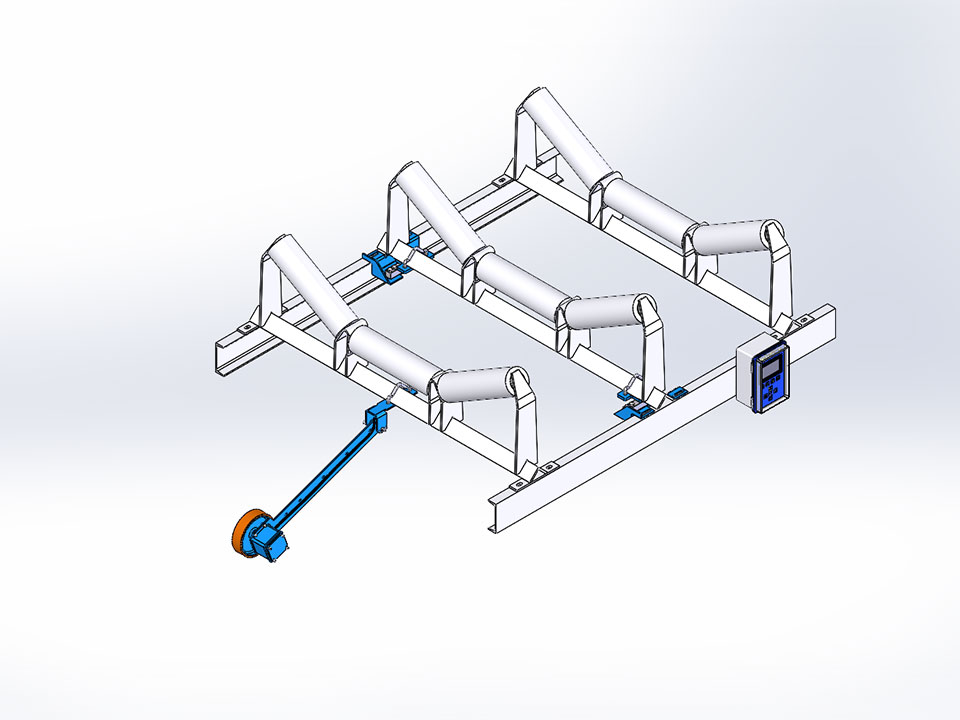

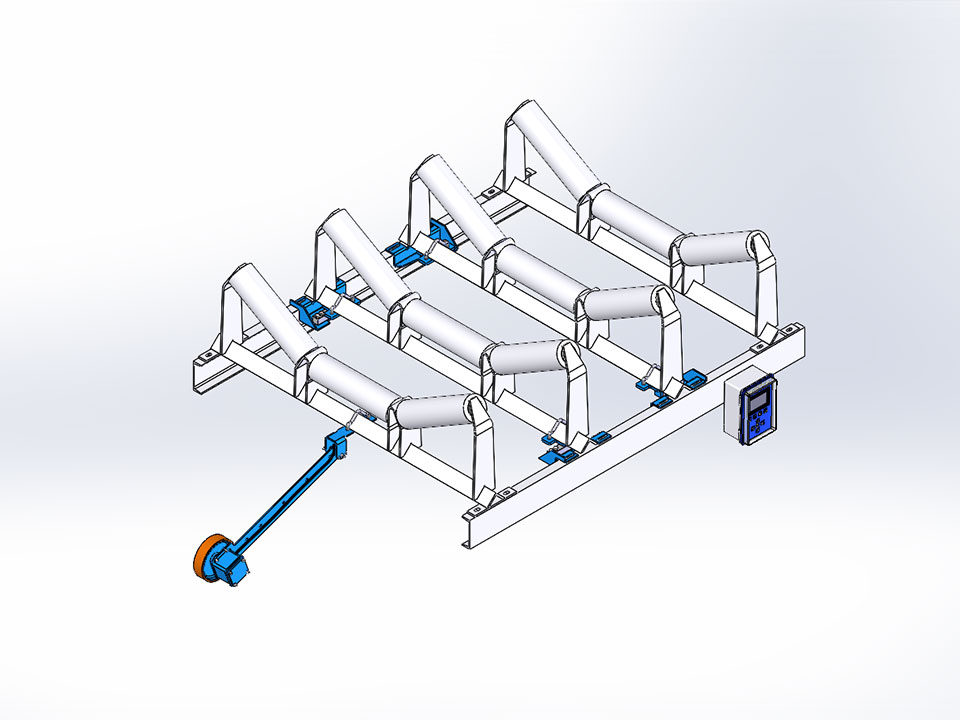

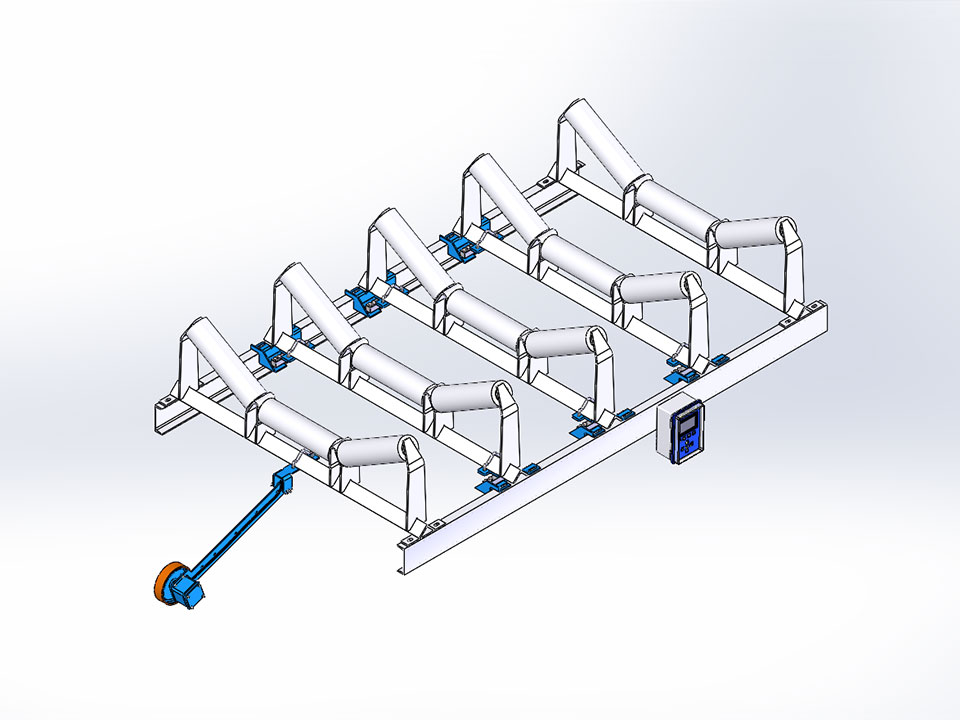

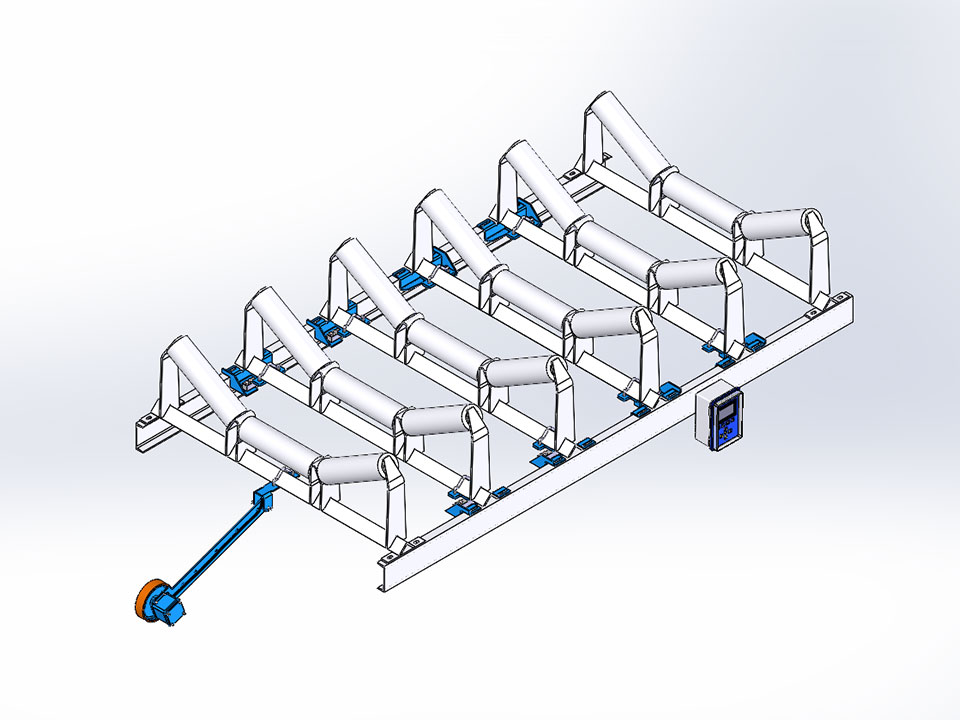

ConveyWeigh offers belt scales in multiple idler configurations (1 thru 4, below). The single idler scale comes with an integral belt speed sensor.

As weighing idlers are added to increase accuracy, we simply supply and install a second, third and forth weighing idler to the single idler system.

This modular concept facilitates efficiency in manufacturing (lowering cost), ease of installation, and allows you to add additional weighing idlers at any time with minimal cost and Installation time.

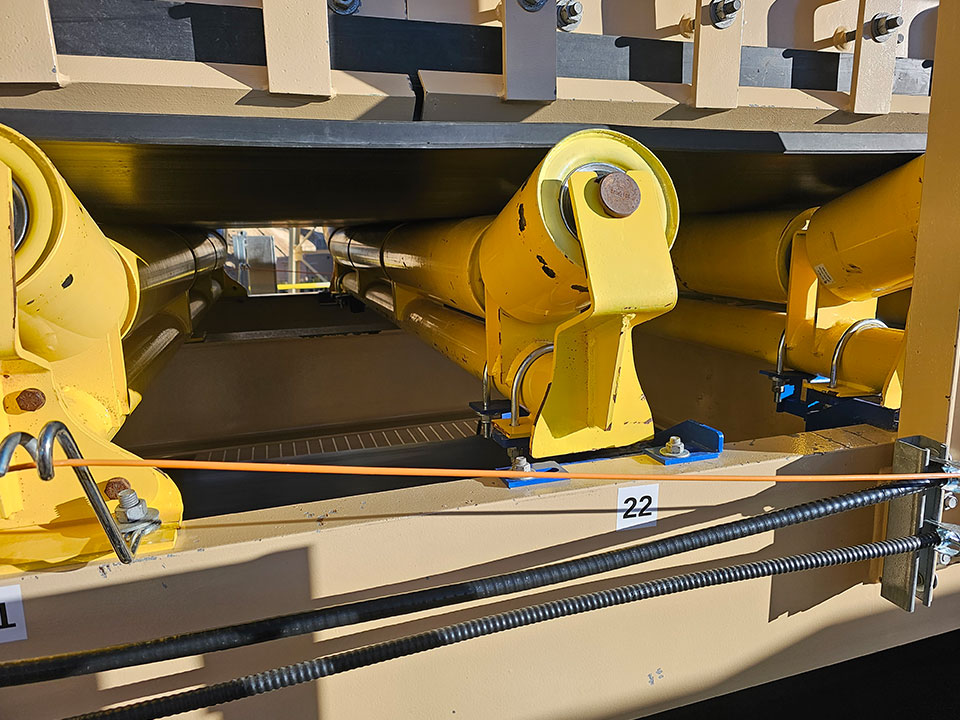

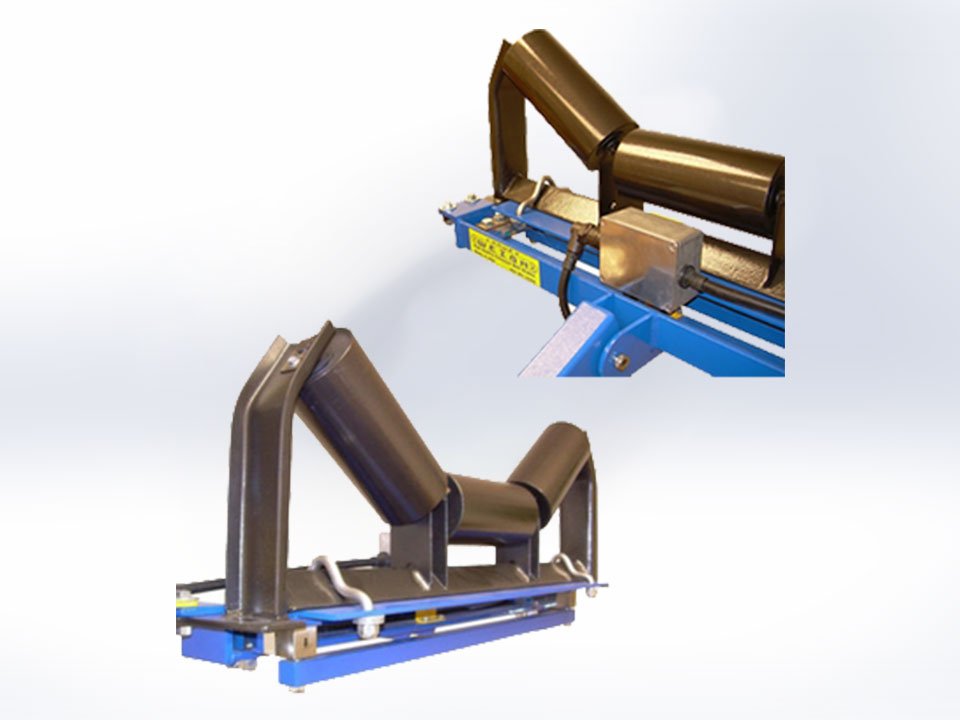

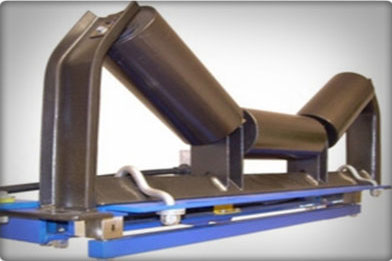

Weigh Bridge

Fully assembled

- Built to fit YOUR conveyor

- HEAVY Steel Construction

- Fully Assembled

- Rigid Low Profile Design

- Test Weight Hanger Bar

- High Torsional Integrity

- High Quality NTEP Approved

- Single Point Shear Beam Load cells

- Universal Idler Mounting

- All Wiring in Conduit

- Ready to Bolt-In Right Out of the Box!

- NEMA 4X Junction Box

- Powder Coat Finish

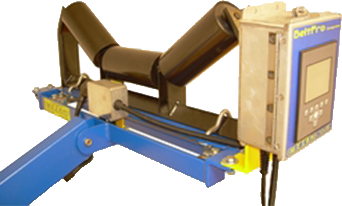

Weight Integrator

- Microprocessor Based

- Back lighted Display

- ¼ VGA 320 x 240 Display

- Multiple Calibrations

- English or Metric Units

- -20 C to +50 C Operation

- 90V AC to 240V AC Site Power

- 12V DC or 24V DC Equipment Power

- Remote Totalizer Output

- Menu Driven, Easy Calibration

- RS232, 422, 485 Serial Output

- Remote Rate-Totalizer

- 0-10V, 4-20Ma Analog Output Card

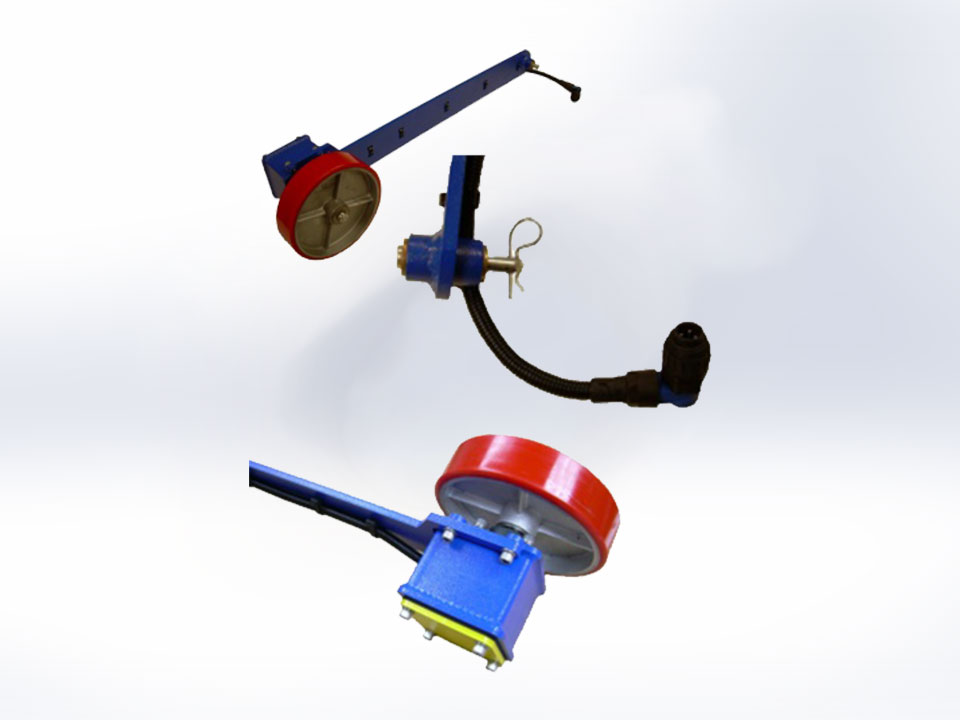

Conveyor Belt Speed Sensor

- Integrated into the Weighbridge

- Runs on the Return Belt (Clean Side)

- Heavy Steel Arm

- Bronze Bushing Pivot

- Stainless Steel Pivot Pin

- All Wiring in Flexible Conduit

- Smooth Running, NO Bounce

- Polyurethane Coated Steel Wheel

- Industrial Bearings

- Water-Tight Design

- Non-Contact Speed Encoder

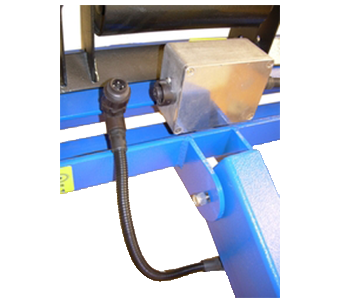

Exclusive Speed Sensor Wiring Connector

The speed sensor cable comes with a watertight connector that allows easy hookup of the speed sensor after the scale in installed. Just plug it in and Weigh. No more standing on your head wiring a scale under a belt.

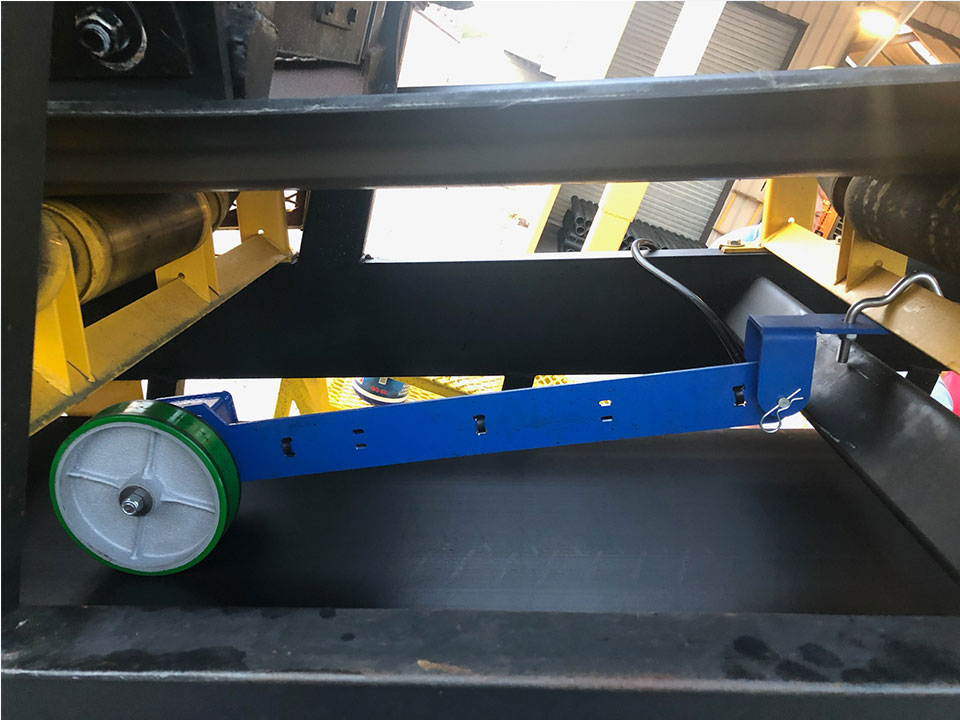

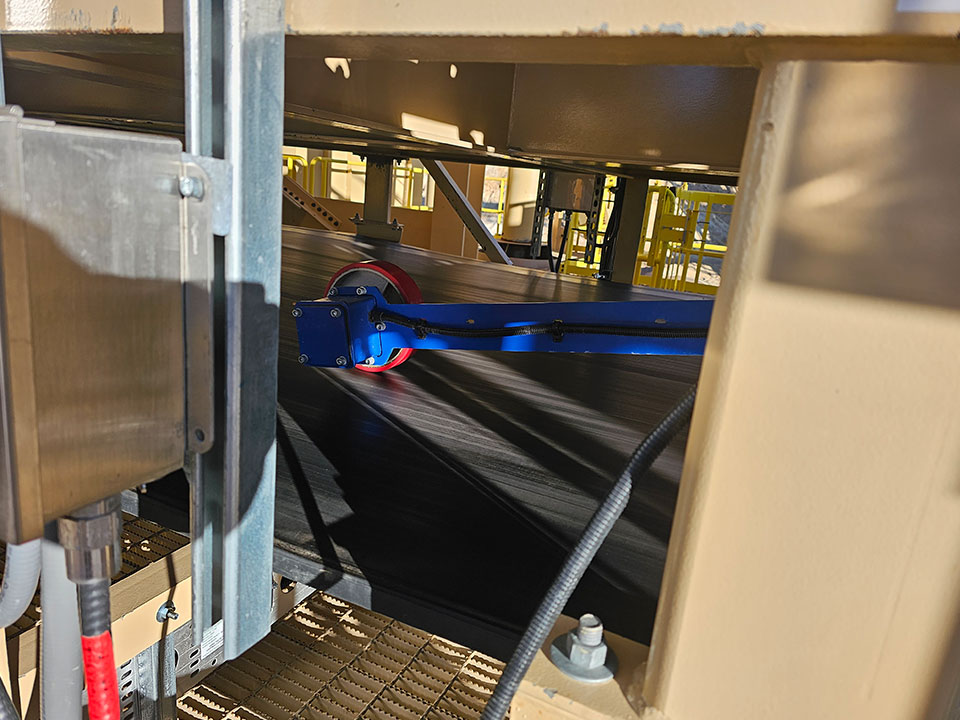

Conveyor Belt for Mining Industry

All ConveyWeigh Belt Scales are Shipped Completely Ready for DROP-IN Installation. Full Assembled — NOT a Kit Scale!

- Integrator Mounted

- All Wiring in Conduit

- Pre-Wired and Tested

- Scale Parameters Pre-Set

- Minimal Assembly Needed

- Easiest Scale to Install

International Technical Assistance

Contact Us

Our Address

6164 Wilding Rd, Ravenswood, WV 26164, United States