Our Products

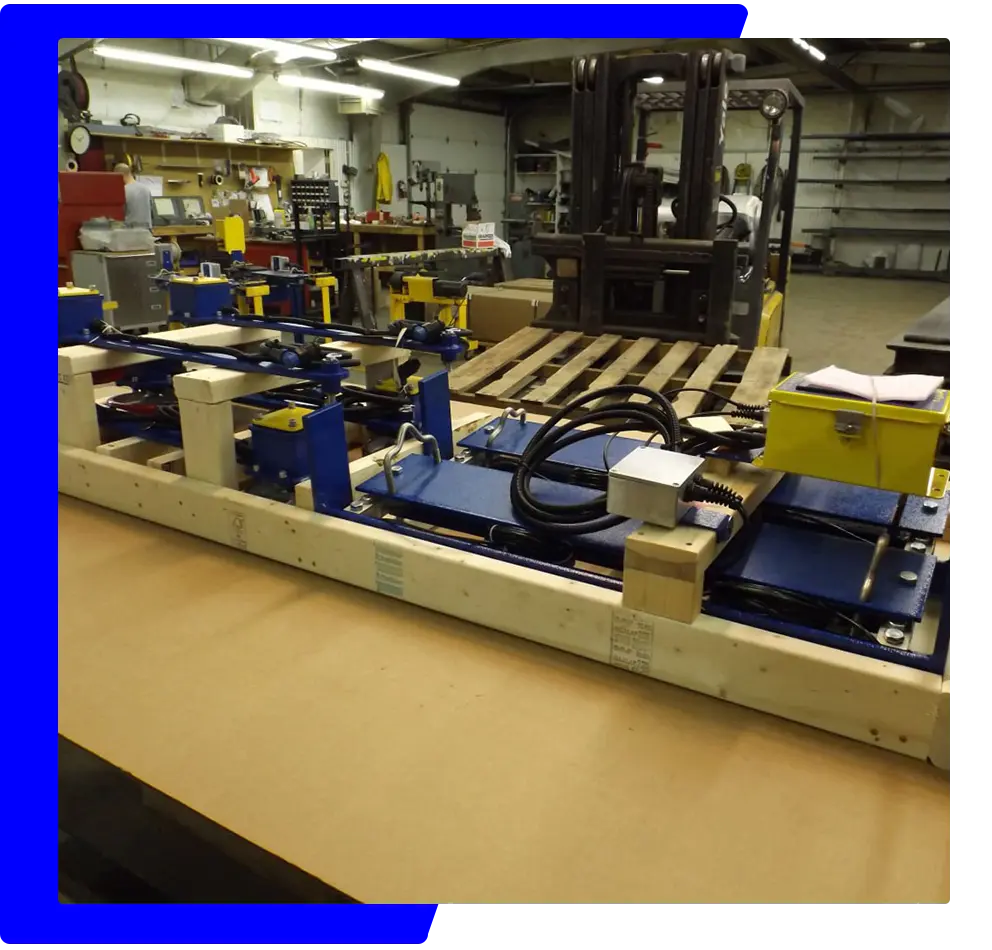

Weigh Feeders

Convey Weigh Belt Pro Weigh Feeders are each custom built per application. Our Weigh Feeders offer “State of the art” components and matching technology. Convey Weigh Weigh Feeders are variable speed relatively short conveyors constructed of stainless, zinc coated, or mild steel (painted) framing. Each Weigh Feeder utilizes a custom built full suspended scale frame. Weigh Feeders are designed for variable programmed bulk material/s flow rates and downline equipment control. Designed for light duty or heavy duty applications with remarkable accuracy at (+/-) 0.5% -.025% or better. PLC / man interface. Multiple inputs and custom programming available.

Read MoreConveyor Belt Scales

Our conveyor belt scale will allow you to measure and log the total weight that has traveled across your conveyor while in motion. ConveyWeigh offers a low-cost and easy to install scale to keep track of your production. ConveyWeigh's standard scale will work with all CEMA style idlers but we also make custom scale frames to work with any conveyor. Just bring us your application and we can make it work.

Read More

About Us

Convey Weigh was formed to fill a need for an inexpensive, quality solution for belt scale applications. Our belt scale products were developed using our over 70 years of combined experience in the belt scale weighing industry. Our scale design utilizes what we have learned over the years selling,installing, calibrating and servicing most every brand of belt scale. We examined all the strengths and weaknesses of other manufacturers' belt scales and built our scales with two objectives.

Our weighbridges are built in a modular form from heavy steel and use high quality NTEP approved load cells. Our speed sensors are also heavy steel construction, have a cast iron core with polyurethane contact outer wheel. It uses sealed industrial bearings and utilizes a unique non-contact speed sensing element and the units do NOT bounce. Our integrator is “state of the art” microprocessor controlled electronics with special attention to the software to ensure very simple operation, plain English displays on the screen, simple calibration routines all housed in a NEMA 4X composite enclosure. Our scales are shipped pre-wired for easy installation.

Industry Applications & Installations

Industry Applications

- Aggregates

- Sand

- Coal

- Wood Chips

- Food

- Animal feeds

- Scrap metal

- Recycling

- Grinding machines

- Crushers

- Mobile machines

- Ore processing

Installations

Our scale frame uses your existing Idlers with the attaching footpads removed. The speed sensor and calibration test weights attach to the existing Idlers as well allowing for quick installation.

We offer supervised installation assistance to anywhere domestic or international. We will fly out an experienced technician who is fully insured to help with installation, calibration and training.

This is an excellent option for odd conveyors and mobile machines as the technician can help modify the scale/structure on-site.

Belt Scale Cellphone Texting

The scale can be polled anytime for the current scale production information. The unit will respond with the daily total, current belt speed and current scale flow rate. An excellent option for seeing production anytime, anywhere.

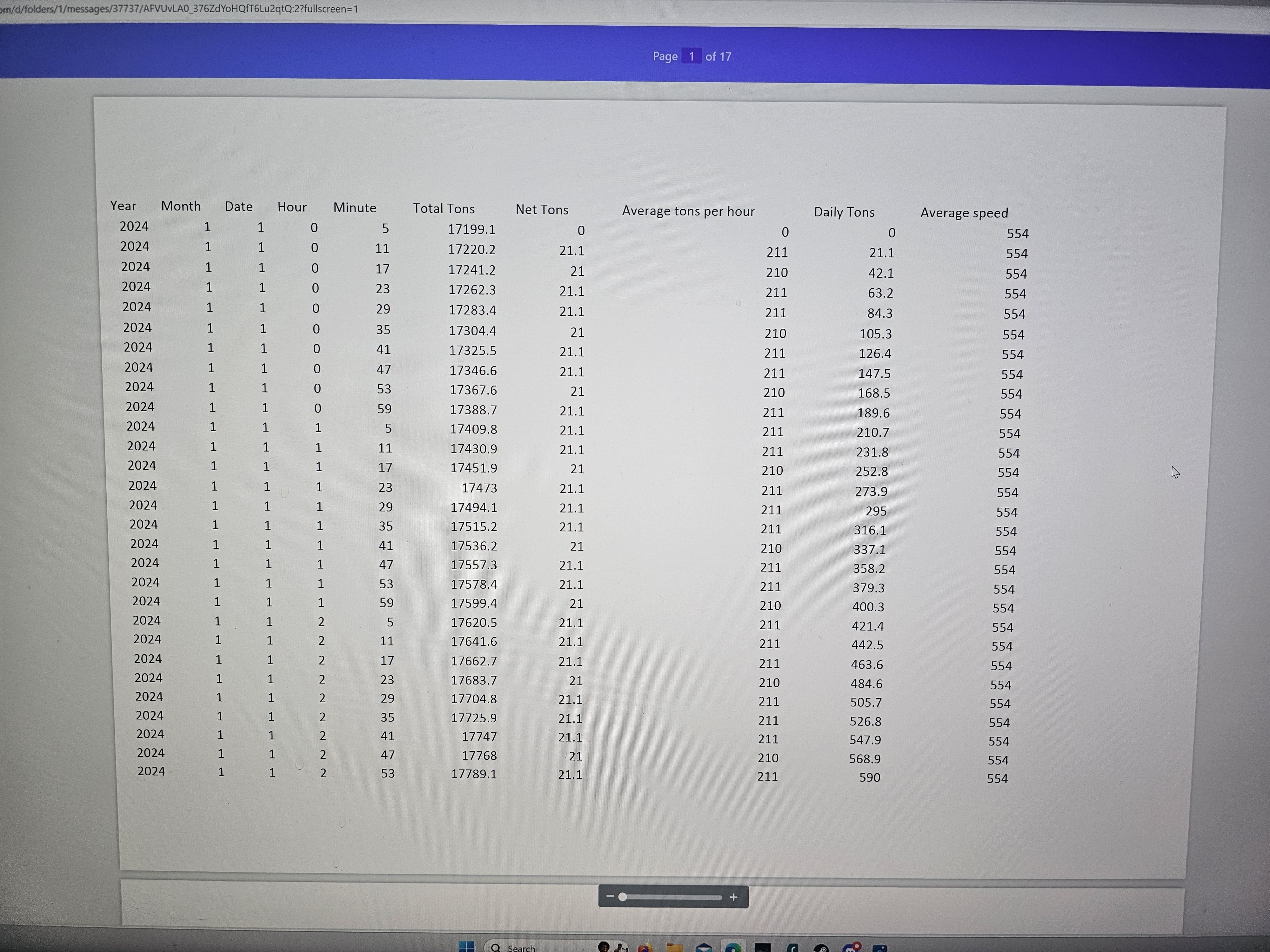

Belt Scale Cellular Data Collection

The scale unit collects real time scale data every 6 minutes and records the numbers in a Microsoft Excel spreadsheet. The scale emails the report at midnight every day to multiple selectable email addresses.

Data includes date and time, total weigh accumulated for the unit, net weight conveyed in the 6 minute period, average flow rate in the 6 minute period and a daily total weight.

Recipient email address can be added or deleted - changed via any cellphone texting application.

Warranty & Specs

All ConveyWeigh equipment comes with a 1-year guarantee from the date of shipment to be free of defects in materials and workmanship.

International Technical Assistance

Contact Us

Our Address

6164 Wilding Rd, Ravenswood, WV 26164, United States